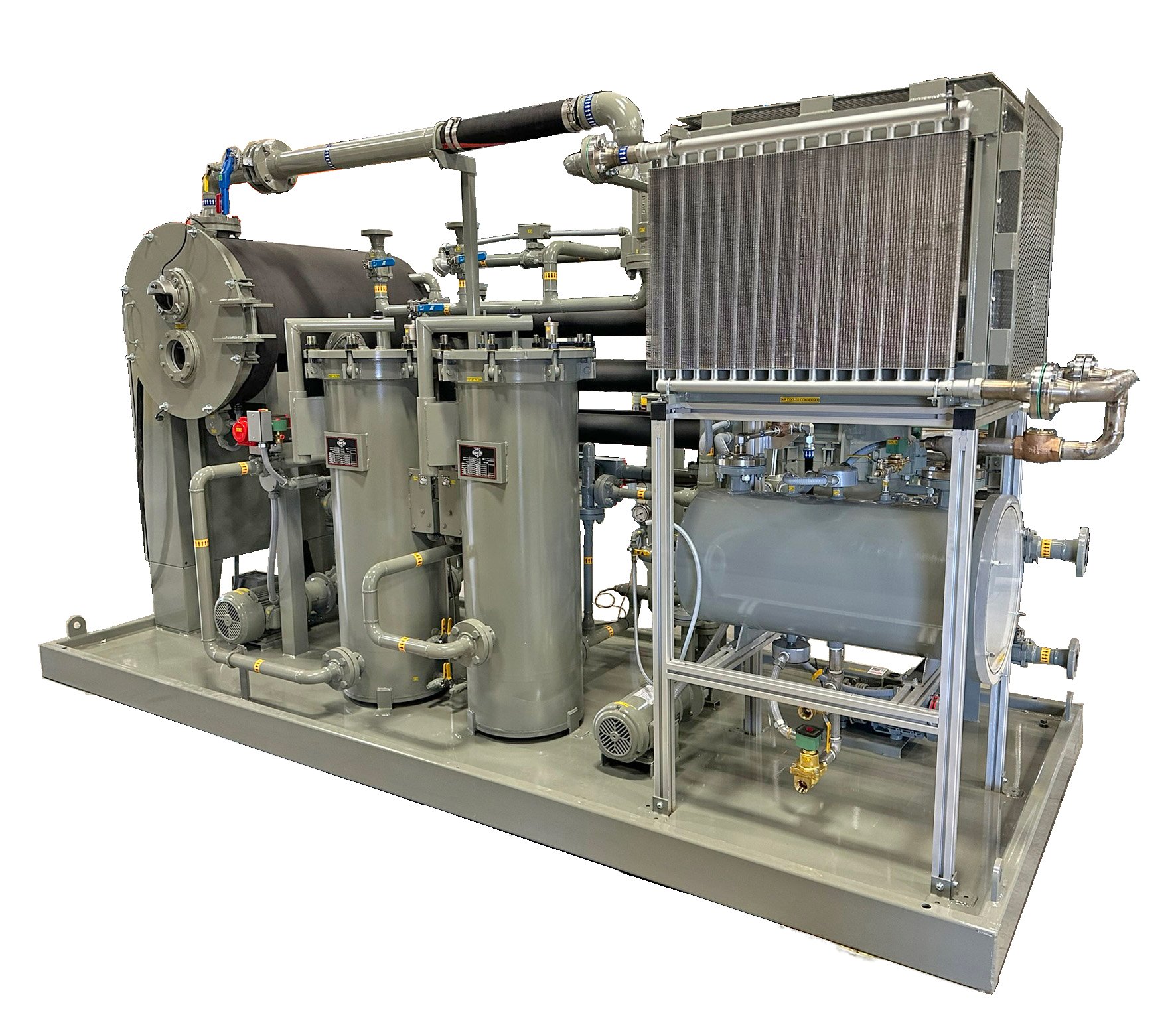

Low Vacuum Purification Systems for Turbine and Hydraulic Applications

Description: Designed to reduce moisture, gas and particulate levels in a wide variety of mineral and synthetic oils such as turbine lube, hydraulic and gearbox oils. Maintenance of such liquids not only extends the life of the liquid; it also improves the performance of the related piece of machinery and extends its life.

Contaminants removed:

Water: Reduction of water content in a single pass by 0.35 – 1.5% of the full flow rate of the unit depending on oil inlet temperature and the type of condensing system selected (slugs of free water should be avoided through settling, floating suction or other means ahead of the purifier). Ultimate reduction of soluble water content to better than 50 ppm below saturation.

Dissolved Gas: Removal of soluble gases and air to < 50% of the saturation level in a single pass through the system at full flow rate.

Particle Removal: To the nominal rating of the user-selectable filter media. Typical systems have both inlet roughing filter and outlet polishing filter. Media for acid, sludge and varnish removal are also available.

Standard features and components:

Flow Rates: 75, 150, 300, 600, 900, 1200, 1500, 1800, or 2400 USgph

Heater: To raise oil to drying temperature: 120-160°F

Vacuum: ≤ 26-28.5 inHg. Vane or claw vacuum pumps available.

Condensers: Air-cooled is standard; water-cooled and closed loop cooled are available for higher ambient installation and special applications.

Portability: System is mounted on a reinforced steel base with integral drip pan for stationary fixed installations. Castors, trailers and other portability options are also available.

Click the Low Vacuum Purification Systems Flyer to download a single-page flyer.